Protecting Mass Timber from Fire, Mold, Distortion and Rot

Aug 23, 2023

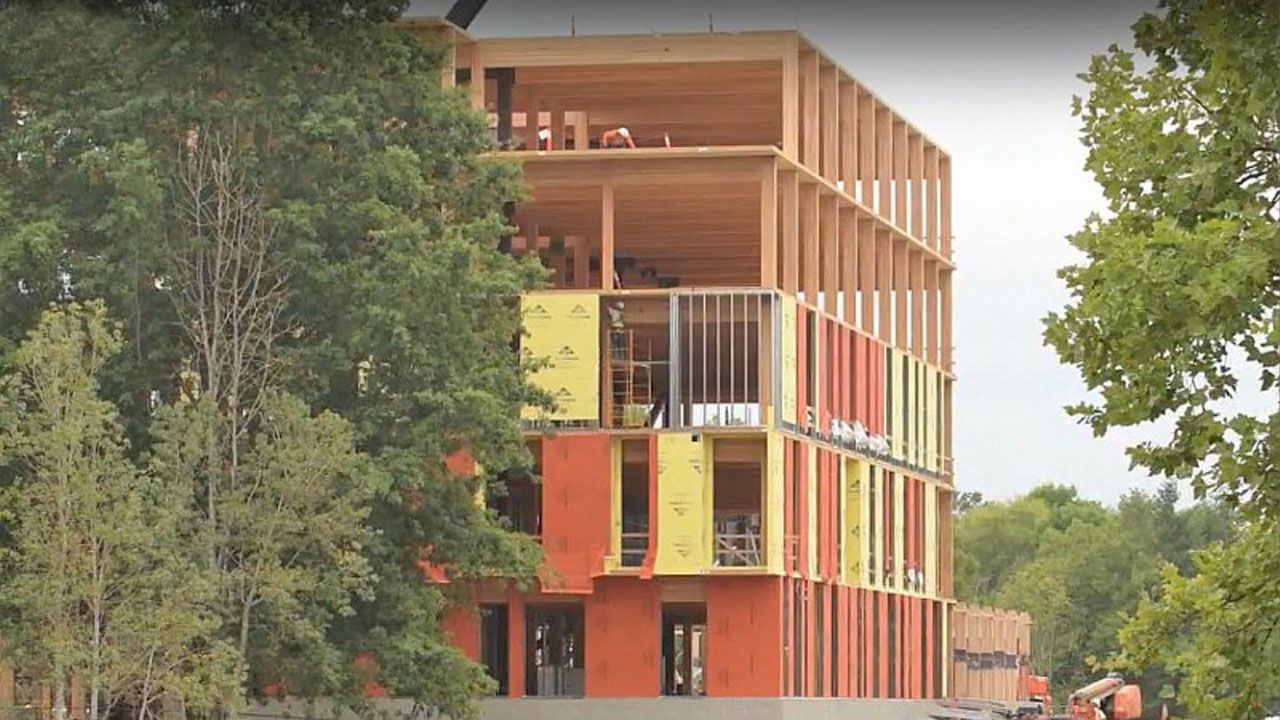

Mass Timber has become an important tool for reducing embedded carbon in new construction and utilizing renewable resources. As it’s becoming more and more common, Mass timber is building past boundaries and has been used to construct buildings as tall as 25 floors.

Mass timber replacing energy intensive steel and concrete

By replacing energy intensive steel and concrete it takes a big bite out of the energy consumed to build a building and modular panels, popular for many mass timber projects, is making that even easier. In turn, protecting mass timber to reduce the effects of fire and moisture is paramount to its structural effectiveness and desired aesthetic.

Part of the allure of mass timber is the richness of the timber left exposed. This was once limited by Fire codes but that is changing with the adaptation of new testing standards and introduction new materials. Testing has proven that as mass timber components burn, the charred residue protects the core, leaving its structural capacity intact. Exterior wall components may require a non-combustible vapor permeable membrane that protects from flame spread. Wall assemblies tested to NFPA 285, which measures fire propagation characteristics, are vital for mass timber, and should be considered on every project.

Protection of excessive moisture exposure to mass timber

Fire isn’t the only threat to Mass timber, moisture degradation of components can jeopardize the timber’s appearance and is costly to remediate. This is easily exacerbated by the fact that Mass timber is often exposed to both the weather in-transit AND during construction. That can mean a lot of water! This excessive moisture exposure can lead to mold growth, dimensional changes, and rot. There are key strategies to protecting mass timber that will save manufacturers, contractors and developers time and money. Addressing it correctly the first time is paramount.

So, where do you start? The production facility is the best place to implement protection for mass timber components! By applying moisture shedding and vapor permeable membranes prior to transport you can reduce damage throughout the building process.

When the material hits the project site, it’s all about protection! It is vital to identify the appropriate membrane for each mass timber component. Flooring members should be protected with a non-slip membrane to provide a safe work environment, continue drying the assembly, and to keep bulk water out. Internal structural components should be protected with a highly permeable protective membrane to continue the drying process. Exterior components should be protected from the weather with a highly permeable air and moisture barrier to release vapor and shed bulk water.

Protect mass timber with VaproShield

Need a solution? VaproShield is a pioneer in the protection of mass timber projects. Whether factory or field installed, we have the appropriate membrane to help protect your project against fire, mold, distortion, and rot. Please click “here” to upload our brochure entitled “Mass Timber Building Enclosure Design Guide”. Please visit us at www.northwestpartnersllc.com or 206-784-0920 for more information or a presentation. AIA and CE available!